Nikoo Samadi

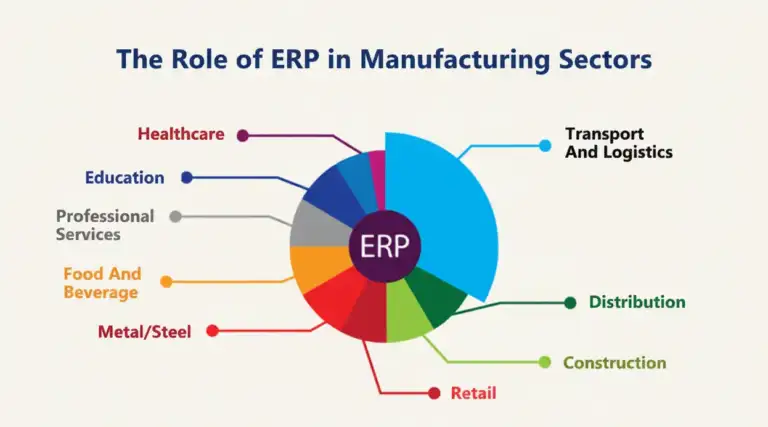

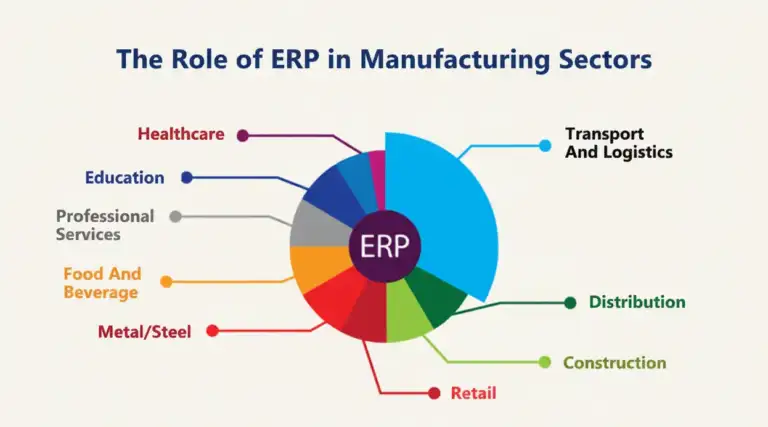

Manufacturing is made up of many interconnected components. People, machines, and materials must all work together. Production slows down and costs increase when these components are out of sync. Many businesses use ERP modules for manufacturing to handle this.

The most important aspects of production are handled by these modules. They simplify work flow and serve as a link between the shop floor and the larger company.

This guide goes over the main manufacturing ERP modules, explains how they work together, and shows why they are essential to managing effective operations

ERP Modules for Manufacturing: What Are They?

The building blocks of an ERP system are modules. Each of them addresses a specific sector of the business, such as finance, sales, or human resources. The modules link together so that data moves freely in one comprehensive system.

Producers are always focused on production. The developed modules under this are usually grouped as ERP modules for manufacturing. These include supply chain and shop floor processes such as what to produce, ordering the right materials, tracking progress, and maintaining quality compliance.

The other modules support manufacturing ERP modules. Production planning and inventory, for example, link so that materials are in place. Quality control and procurement work together to ensure consistency in what gets purchased. Finance uses production cost data to measure profitability.

The integration of these modules closes the gaps left by disjointed systems and creates a complete view of operations.

Simplify Your Decision with GEM365

Get in touch with GEM365 to guide you through the process and get consultation for free.

Key ERP Modules for Manufacturing

The following are some of the most important ERP modules for manufacturing. Each module supports production in a specific way, and together they create a system that helps manufacturers run operations with less waste and more control.

Production Planning and Scheduling

One of the key ERP modules in manufacturing is production planning. A foundation is made by selecting what to produce, when to produce it, and how to use resources. Capacity and demand are balanced by a good ERP program in production planning. It assists managers in scheduling labor, work order assignment, and machine availability. Through this, downtime is minimized as well as bottlenecks.

Bill of Materials (BOM) Management

Every assembly, raw material, and component required to construct a product shows up in the Bill of Materials. The BOM module keeps this data fresh and current. That makes a big difference because small mistakes can cost money unnecessarily or slow up production. ERP ensures that production is always working from the current version of the BOM by plugging changes in supplier data or part design directly into it.

Planning Material Requirements (MRP)

When and what materials will be needed are programmed by the MRP module. Excess inventories that keep money tied up are eliminated, along with output halts due to shortages. MRP ensures that materials are in place when required and in proper quantities by connecting with procurement and inventories.

Control of the Shop Floor

Production activity is regulated by shop floor control. Work performed, labor hours, machine use, and completion of jobs are monitored. Managers receive current data so that, as soon as there are delays or problems, an immediate response is possible. This improves visibility and maintains production lead times.

Inventory and Warehouse Management

ERP manufacturing software usually includes inventory, yet it is critical to producers. The module follows finished products, work-in-progress, as well as raw materials. By connecting with production planning, the software makes sure supply is available when needed without creating waste.

Quality Management

Quality management modules keep standards in check along the production line. They track defects, keep test results, and aid in compliance with industry specifications. By linking procurement with quality information, firms can make sure vendors meet required standards.

Maintenance

Production may be interrupted when machines break down. The maintenance module monitors repairs, schedules preventive maintenance, and keeps equipment history. This helps extend equipment life and reduce unexpected breakdowns.

Analytics and Cost Management

Manufacturers must know the actual cost of production. Data on labor, materials, and overheads are gathered by the cost management module. Profitability by product, order, or customer is displayed in its reports. Leaders are better able to decide on pricing, budgets, and resource use as a result.

Benefits of ERP Modules for Manufacturing

Using the right ERP modules for manufacturing changes how a plant runs. Instead of juggling spreadsheets and disconnected systems, managers and workers see the whole picture in one place. That shift brings a set of clear benefits:

Better visibility

When production, inventory, and quality are tied together, everyone knows what’s happening in real time. Managers can catch problems early instead of after the fact.Less waste

Accurate planning reduces extra stock and prevents shortages. That means less money tied up in materials and fewer stoppages on the line.Stronger quality control

Quality modules track standards from raw materials to finished goods. This consistency helps avoid rework and keeps customers satisfied.Lower costs

ERP gathers cost data from every step of production. Leaders can see what drives expenses and act before small issues become big losses.Smarter decisions

With analytics built in, decision-makers have reliable data to guide budgets, pricing, and schedules. No guesswork.

Together, these benefits make day-to-day operations smoother and long-term planning more reliable.

How to Pick the Best Manufacturing ERP

ERP systems are not general-purpose. Some are service businesses, and some are retail. A system that makes sense is one for manufacturing that supports the production process; is directly connected to the shop floor; and has logic for goods moving through a plant. As a place to begin, consider the fundamentals. Look for a system that has the most fundamental modules for manufacturing: cost control, quality, inventory, and production planning. Those are the basics.

Next, you should consider scale. A large factory has different needs than a small shop, but both benefit from a feature (but not limited to) system that allows them to scale.

The correct ERP will not limit in terms of growth, so as you grow you can invest – and have options. Another test is integration. To ensure decisions are based on the whole picture, and not parts– the system should integrate production and connect finance, purchasing, and sales. Finally, effectiveness.

A system can only be effective if people use it, and the ability to learn the system should be reasonable to ensure it does not interfere with everyday activities.

Final thoughts

Manufacturing is reliant on numerous moving parts working together. ERP modules for manufacturing condense those parts and allows managers and team members to access the same data to make informed decisions. The modules work in all areas including planning, inventory control, quality, and costs, and allow work to flow and reduce or eliminate the gaps that slow production timelines.

Finding an ERP that works for all manufacturing companies is a challenge because there are many variations in how manufacturers operate. If you would like to see how this can work for your specific operations, we can help!

We offer free consultations to discuss your options and GEM365 was designed for manufacturers. Click here to arrange a consultation.

Table of Contents

Read more

Forbes Reveals the Best Cloud ERP: Here’s Why Business Central Wins

How the Microsoft Power Apps Platform Transforms Manual Processes

Top Power Automate Workflows Every Business Should Use in 2025