Nikoo Samadi

Inventory is one of the most important aspects of any business that creates products. Parts, finished goods, and raw materials must move at the right time and in the right quantity. When inventory isn’t managed properly, costs increase, production slows down, and orders become delayed. This is where an ERP inventory management module truly adds value. It helps manufacturers track their stock, control its movement, and connect it seamlessly with the rest of the business.

As a result, managers no longer need to rely on outdated records or make decisions based on guesswork. Instead, they can access accurate, real-time information and make confident, data-driven choices.

In this blog, we will explore the role of the ERP inventory management module within manufacturing ERP systems. Specifically, we will discuss the challenges it solves, the features it provides, and the benefits it delivers. Moreover, we’ll address common hurdles during implementation and explain how manufacturers can maximize the value of this essential ERP module.

Common Inventory Challenges in Manufacturing

Manufacturers often face inventory problems that slow them down and reduce profits. Recent data highlights why better tools are essential.

First, stockouts and overstocks create serious issues. In 2020, the global cost of inventory distortion reached $1.8 trillion. However, companies can reduce inventory costs by around 10% simply by minimizing these problems.

In addition, inventory losses are a growing concern. More than 40% of manufacturers believe they will lose stock in the next year due to theft, damage, or inaccurate counting.

Another challenge is unpredictable demand. When manufacturers cannot forecast accurately, they often order either too much or too little. As a result, both overproduction and shortages disrupt operations. Poor demand forecasting also increases the risk of running out of stock or storing excess goods.

Moreover, inaccurate data makes the situation worse. Many teams still rely on spreadsheets or disconnected systems. When records don’t match actual inventory, production slows, errors occur, and employees spend hours reconciling data manually.

Finally, holding too much stock creates extra costs. Idle inventory ties up money and takes up valuable warehouse space. In one study, companies identified high holding costs as a major reason for rising prices.

Therefore, it’s easy to see why more manufacturers are adopting ERP inventory management modules. With real-time tracking, structured data, and full integration with stock control systems, ERP solutions help reduce waste, delays, and costly mistakes.

Simplify Your Decision with GEM365

Get in touch with GEM365 to guide you through the process and get consultation for free.

Key Elements of an ERP Module for Inventory Management

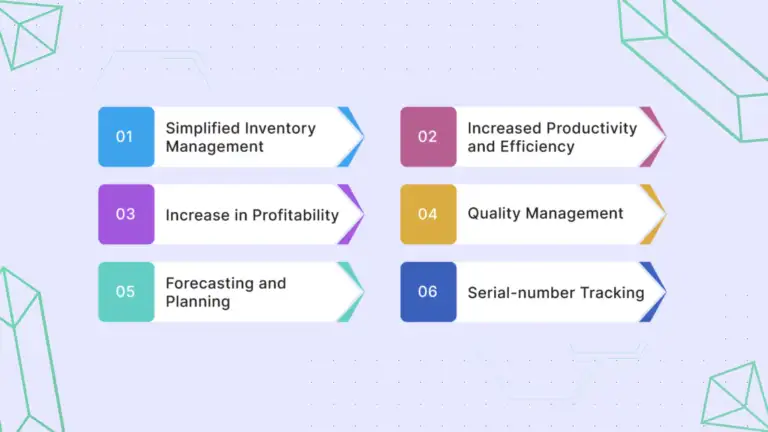

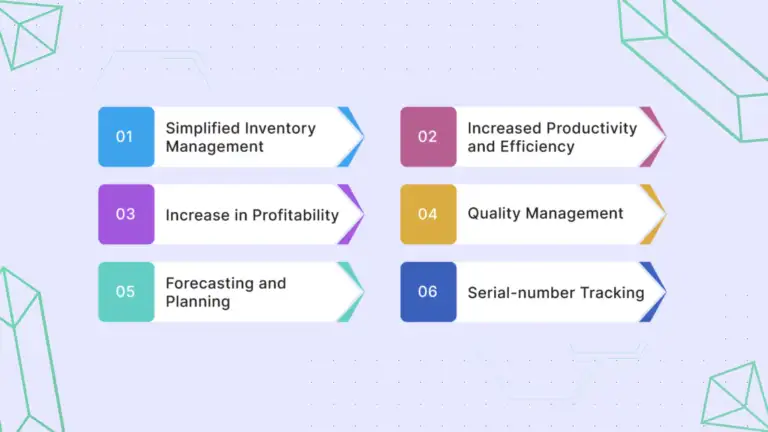

An inventory management module includes several essential features that help manufacturers control materials, reduce waste, and avoid costly mistakes. Together, these tools give production teams the visibility and control they need to stay efficient and accurate.

Tracking Inventory in Real Time

As stock levels fluctuate across locations, the system displays them. It keeps track of finished goods, work-in-progress (WIP), and raw materials. According to NetSuite’s Manufacturing Inventory Management Guide 2025, maintaining precise real-time inventory tracking across production and warehouses is crucial. In addition, it helps manufacturers balance excess stock and shortages effectively.

Automated Alerts & Reorder Triggers

By setting minimum levels, the module enables the system to automatically notify you or place orders when stock levels are low. This lowers the possibility of stockouts. How to Choose the Best ERP for Manufacturing – Expert Guide 2025 notes this as a key benefit in improving ERP supply chain module performance.

Management of Suppliers and Vendors and Assistance with Procurement

Good ERP inventory management modules integrate procurement functions. They help manage vendor performance, track lead times, and ensure timely material delivery. According to NetSuite’s guide, tasks such as vendor management and procurement should connect directly to inventory.

Tracking the Location of Warehouses, Tracking Lots and Serial Numbers

Each unit’s location can be precisely tracked thanks to features like bin-level tracking, lot/serial number support, and environmental conditions (if applicable). This aids in managing recalls and identifying problems. Among the most crucial features listed in Rootstock’s Top Features in Manufacturing Inventory Management Software are complete traceability and lot and serial number tracking. Such features are often part of a warehouse management ERP system.

Forecasting Demand and Optimizing Inventory

Using demand signals, seasonality, and historical data makes it easier to predict what inventory is required and when. Netsuite emphasizes that accurate forecasting enables manufacturers to avoid overstocking or understocking and ensures efficient inventory management.

Connectivity with Additional ERP Modules

Inventory is not a standalone system; it connects with finance, sales, purchasing, and production planning. As a result, integrating these functions prevents delays and inconsistencies caused by information silos. Moreover, the Manufacturing ERP Features & Benefits guide identifies inventory control as a key component of effective manufacturing ERP systems.

How These Characteristics Avoid Flaws

Poor material control is frequently the first sign of manufacturing defects. By making stock data accurate, accessible, and interconnected, an ERP inventory management module lowers this risk.

The right materials are available at the right time thanks to real-time inventory tracking. Employees are less likely to use the incorrect part or overlook a component when they are not dependent on out-of-date records. Real-time visibility in ERP reduces material errors and scrap.

Tracking lots and serial numbers aids in identifying quality issues. The system pinpoints the precise units that are impacted if a flaw is discovered in a single batch. This lowers recall and rework expenses.

Defects are also reduced through vendor and supplier management. The system identifies problems with late or subpar deliveries by tracking supplier performance and connecting purchase orders to inventory. This lessens the chance of errors brought on by faulty inputs.

Hasty last-minute purchases are avoided with automatic reorder points. Emergency purchases frequently result in lower-quality replacement materials. Manufacturers can source materials on time and maintain consistent quality with the help of stock alerts.

Lastly, integrating inventory data with production records and inspection results ensures alignment with production and quality modules. Consequently, manufacturers experience fewer discrepancies between actual and planned production.

These characteristics work together to control materials before they are used in production, strengthening the foundation for defect prevention.

How These Characteristics Improve Engagement

Manufacturers are subject to strict safety, tracking, and reporting rules. By guaranteeing that records are accurate, complete, and easily accessible, an ERP inventory management module helps in meeting these requirements.

One of the most essential instruments for security is tracking. Every item can be tracked back to its original source with lot and serial tracking. The system instantly provides proof of material origin or handling when regulators request it.

Another advantage is that the records are audit-ready. Manufacturers can extract reports straight from the system rather than assembling spreadsheets or paper logs. This lowers errors and demonstrates process control to auditors. One important component of ERP inventory systems for regulated industries, according to Rootstock, is compliance reporting.

Compliance is further strengthened through integration with quality modules. If a flaw is discovered, the ERP associates it with the precise supplier lot, batch, and inspection record. This produces a thorough audit trail that satisfies legal requirements.

Lastly, accurate inventory data improves safety and environmental compliance. Hazardous materials, for instance, can be tracked by shelf life and location. This keeps dangerous or out-of-date stock out of production.

By combining traceability, reporting, and integration, the ERP inventory management module helps manufacturers stay compliant without adding heavy manual work.

Best Practices & Implementation Difficulties

Although implementing an ERP inventory management module may provide significant benefits, many manufacturers face difficulties during the process.

First, data migration poses a major challenge. Errors often appear when transferring inventory records from spreadsheets or outdated systems. As a result, incorrect or incomplete data can cause issues with the new system. According to a 2024 Panorama Consulting survey, poor data quality is one of the main reasons ERP projects fail to meet expectations.

Another challenge is user adoption. Staff members may resist the change or continue using outdated procedures if they do not receive proper training. Consequently, the module’s benefits remain limited. Industry reports show that practical training and transparent change management significantly reduce these risks.

Integration can also be difficult. Purchasing, production, sales, and finance must work seamlessly with inventory. Otherwise, data silos persist if the links are not correctly configured.

To address these challenges, manufacturers should pilot test the system before full launch, involve warehouse and production staff early, and clean data prior to migration. In addition, clear communication and ongoing training increase user confidence. Finally, establishing measurable goals—such as reducing stockouts or improving stock accuracy—ensures the project delivers real value.

Final Thoughts

Every manufacturing operation centers around inventory. Production slows and costs increase when it is not properly managed. Manufacturers can maintain inventory control by using an ERP inventory management module, which provides the necessary structure and visibility.

We have seen how the module lessens common issues like stockouts, excess inventory, and inaccurate records. Real-time inventory tracking, reorder points, supplier management, traceability, and integration are some of its features that support industry compliance and defect prevention.

Although there are obstacles to implementation, manufacturers can reap long-term rewards with clear objectives, robust training, and clean data. As a result, there are fewer mistakes, expenses are reduced, and the capacity to satisfy customer demands is strengthened. For firms using Business Central, or looking at broader warehouse management ERP or ERP supply chain modules, this approach provides a strong foundation for growth.

Table of Contents

Read more

Forbes Reveals the Best Cloud ERP: Here’s Why Business Central Wins

How the Microsoft Power Apps Platform Transforms Manual Processes

Top Power Automate Workflows Every Business Should Use in 2025